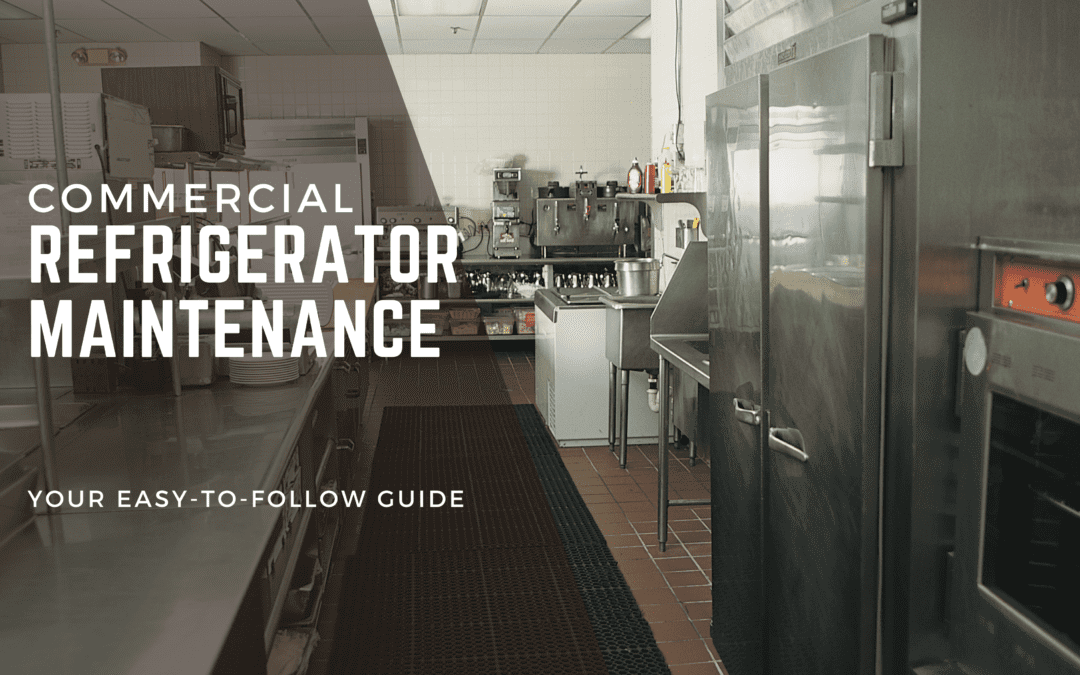

Commercial Refrigerator Maintenance: Your Easy-to-Follow Guide

Introduction

Maintaining your commercial refrigerator isn’t optional; it’s crucial for preventing costly breakdowns, protecting your food, and ensuring your kitchen runs smoothly. Think of commercial refrigerator maintenance as an investment – simple tasks today can save you thousands of dollars in repairs and downtime in the future.

In this comprehensive guide, we’ll cover everything you need to know about commercial refrigerator maintenance:

- Essential tasks to protect your refrigeration equipment

- How to troubleshoot and fix common problems

- Tips to extend the lifespan of your refrigerator

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Cleaning Condenser Coils: Your Commercial Fridge's Key to Efficiency and Preventing Overheating

Your refrigerator’s condenser coils are essential for releasing heat. When clogged with dust, the unit overworks and can fail prematurely. For optimal commercial refrigerator maintenance, make coil cleaning a priority.

Frequency: Clean at least every 3 months Tools: Coil brush, vacuum cleaner

Steps:

- Safety First: Unplug the refrigerator.

- Find the Coils: Located at the back or bottom of the unit.

- Brush and Vacuum: Gently loosen dust with the coil brush, then vacuum it away.

The Drip Pan & Drain Hole: Stop Odors and Blockages in Your Commercial Refrigerator

A clean drip pan and drain hole ensure proper drainage and prevent issues that compromise fridge performance. Include this in your commercial refrigerator maintenance routine:

Frequency: Monthly

Tools: Sponge, mild detergent or vinegar solution

Steps:

- Locate: Find the drip pan and hole under the refrigerator.

- Clean: Empty the pan and clean it and the surrounding area.

Door Gaskets: Ensuring Energy Efficiency and Food Safety in Your Commercial Fridge

Worn-out seals let cold air escape, overworking your refrigerator and risking food spoilage. Regular gasket checks are a vital part of commercial refrigerator maintenance.

Frequency: Inspect every 3 months, replace as needed.

Tools: None for inspection; replacement gasket if needed.

Steps:

- Check the seal: Look for cracks, gaps, or signs of wear.

- Replace: If damaged, follow the manufacturer’s instructions.

Temperature is Key: Ensure Food Safety and Prevent Strain on Your Fridge

Maintaining the correct temperature inside your commercial refrigerator is critical for food safety and minimizing unnecessary wear and tear on the unit.

- Daily Checks: Use a standalone thermometer to verify the accuracy of your refrigerator’s built-in temperature display.

- Safe Range: The ideal temperature range for commercial refrigerators is between 33°F and 40°F (0.5°C to 4°C).

- Professional Standards: For in-depth guidelines on temperature control in commercial kitchens, refer to ASHRAE standards NOTE: it does cost

Interior & Exterior Cleanliness: Beyond Just the Looks

A clean refrigerator is essential for food safety and preventing foul odors.

- Frequency: Weekly for interior, as needed for exterior

- Tools: Soft cloth, mild detergent, warm water

Steps:

- Unplug and Empty: Prioritize safety, then remove all items.

- Wipe Down: Clean all interior surfaces with the detergent solution.

- Exterior Care: Use stainless-steel safe cleaners if applicable.

Air Filters and Ventilation: Help Your Fridge Breathe Easy

Clogged filters cause strain and hinder airflow around the refrigerator unit.

- Frequency: Every 6 months

- Tools: Vacuum cleaner, soft brush

Steps:

- Clean Filters: Ensure filters are fully clean for optimal flow.

- Good Surroundings: Check that nothing blocks the vents.

Defrosting (If Applicable): Get Rid of Ice Buildup

Follow your refrigerator’s instructions for the best results.

- Frequency: Per manufacturer recommendations

- Tools: Soft cloth, plastic scraper (for manual defrost models)

Steps:

- Off/Unplugged: For manual models, start by powering down.

- Let It Melt: Allow ice to melt without using sharp tools.

FAQ

Q: How frequently should I clean the condenser coils of my commercial fridge?

A: For optimal performance, cleaning condenser coils every 3 months is highly recommended.

Q: How do I know if my door gasket needs to be replaced?

A: Look for tears, cracks, or areas where the seal doesn’t firmly make contact with the refrigerator frame. If you can easily slide a dollar bill out when the door is closed, your gasket likely needs replacement.

Q: Are there maintenance tasks that should only be handled by a professional?

A: While routine maintenance is manageable, any task that involves refrigerant, electrical work, or disassembly of major components should be left to a qualified technician.

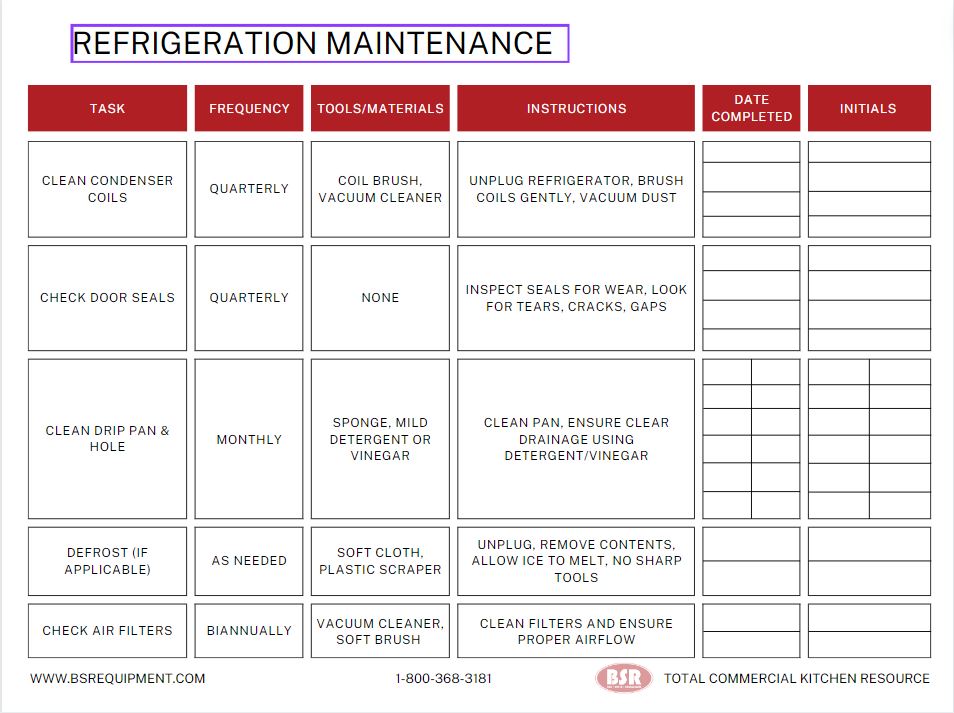

Ready to take control of your commercial refrigerator maintenance? Download our FREE printable chart and start optimizing your fridge’s performance today!