by BSR Marketing | Jan 7, 2025 | Uncategorized

Introduction

As we step into 2025, the restaurant industry continues to evolve, driven by changes in customer expectations, advancements in technology, and a growing focus on both sustainability and memorable dining experiences. Here are some of the top restaurant design trends to watch for as we roll out this new year:

- Nature-Inspired Design

Bringing the outdoors inside has never been more popular. In 2025, expect restaurants to feature:

- Biophilic elements: Incorporating greenery, living walls, and natural light to create calming, nature-inspired spaces.

- Earthy color palettes: Shades of green, terracotta, and beige dominate, complemented by raw materials like wood, stone, and clay.

- Sustainable materials: From recycled furniture to eco-friendly finishes, restaurants are prioritizing environmental responsibility in design choices.

- Flexible and Multi-Functional Spaces

With the rise of remote work and changing dining habits, restaurants are rethinking their layouts. Key features include:

- Adaptable furniture: Modular seating and tables that can be reconfigured for different group sizes or event needs.

- Hybrid spaces: Combining dining areas with coworking spaces or retail corners to maximize usability.

- Outdoor expansions: Weatherproof patios and rooftop dining areas remain a staple, catering to diners who prefer open-air experiences.

- Technology Integration

Smart technology is shaping the future of dining, with innovations that enhance both customer experience and operational efficiency:

- Digital menus and QR codes: Streamlining ordering processes while reducing paper waste.

- Smart kitchens: IoT-enabled appliances and automated systems improve workflow and energy efficiency.

- Immersive dining experiences: AR and VR elements that engage customers and create shareable moments.

- Bold and Unique Branding

Restaurants are using design as a key component of their branding strategy, creating spaces that tell a story:

- Instagrammable aesthetics: Eye-catching murals, neon signs, and statement furniture that encourage diners to share their experiences online.

- Custom lighting: Bespoke fixtures that match the restaurant’s theme while enhancing ambiance.

- Personalized touches: Unique design elements like hand-painted tiles or locally sourced decor that connect to the restaurant’s roots.

- Focus on Sustainability and Wellness

Consumers are increasingly valuing businesses that prioritize the planet and their well-being. Design elements include:

- Energy-efficient systems: LED lighting, energy-saving appliances, and advanced HVAC systems.

- Eco-conscious decor: Upcycled furniture, zero-VOC paints, and sustainable textiles.

- Wellness-focused spaces: Quiet zones, improved air quality, and ergonomic seating to enhance comfort and health.

- Minimalist Luxury

Simplicity meets sophistication in 2025, with a trend towards understated elegance:

- Clean lines and open spaces: Creating an airy, uncluttered look that feels both modern and inviting.

- High-quality materials: Marble countertops, brass accents, and velvet upholstery add a touch of luxury.

- Muted color schemes: Neutral tones with occasional pops of color keep the focus on the dining experience

- Local and Cultural Influences

Restaurants are celebrating their heritage and community through design:

- Regional motifs: Patterns, colors, and materials inspired by local traditions and art.

- Support for local artisans: Handcrafted furniture and decor that reflect the culture of the area.

- Farm-to-table aesthetics: Designs that emphasize a connection to local food sources, like open kitchens or displays of fresh produce.

Conclusion

The restaurant design trends for 2025 reflect a blend of innovation and intention, focusing on creating spaces that are functional, beautiful, and aligned with the values of today’s diners. By embracing these trends, you too can better elevate unforgettable dining experience with your food operations.

Whether you’re planning a new restaurant or refreshing an existing one, keep these upcoming trends in mind to help ensure that your space is both current with the times and ready for the future. Give us a call at 1 (800) 368-3181 or shoot us a message here.

by BSR Marketing | Dec 26, 2024 | Uncategorized

In a fast-paced world of food service, every decision you make can signficantly impact your business’s efficiency, reputation, and bottom line. One area often overlooked is the importance of product warranties when investing in commercial kitchen equipment. Here’s why warranties should be a key factor in your purchasing decisions:

1. Protecting Your Investment

Commercial kitchen equipment is a substantial investment. From ovens and refrigeration units to mixers and dishwashers, these tools are the backbone of your operation. A comprehensive warranty ensures your investment is protected against unexpected breakdowns or defects. This means you can focus on delivering excellent food and service without worrying about costly repairs or replacements.

2. Minimizing Downtime

Equipment failures can disrupt your workflow, delay service, and impact customer satisfaction. Many warranties include expedited repair or replacement services, helping you get back to business faster. Some manufacturers even offer on-site support to minimize downtime, ensuring your kitchen runs smoothly.

3. Cost Savings in the Long Run

While warranties may initially seem like an additional expense, they can save you money over time. Repairing or replacing commercial-grade equipment without a warranty can be costly. A warranty provides financial relief by covering parts and labor for issues that arise during the coverage period.

4. Ensuring Quality and Reliability

Manufacturers that offer strong warranties often stand by the quality of their products. A warranty signals that the company is confident in its equipment’s performance and durability. This assurance gives you peace of mind, knowing you’re purchasing reliable tools for your operation.

5. Building a Long-Term Partnership

Choosing equipment with a warranty can lead to a stronger relationship with the supplier or manufacturer. Many suppliers provide ongoing support and maintenance tips as part of their warranty services. This partnership can be invaluable as your business grows and evolves.

Key Considerations When Evaluating Warranties

- Coverage Details: Understand what the warranty covers—parts, labor, and specific components.

- Duration: Check the length of the warranty and any options for extended coverage.

- Exclusions: Be aware of what is not covered, such as misuse or wear and tear.

- Service Process: Ensure the warranty includes easy access to support and repairs.

Final Thoughts

Investing in high-quality commercial kitchen equipment with robust warranties is not just a smart financial decision—it’s an operational necessity. Here at BSR, we’re committed to helping food service professionals such as yourself make informed decisions about their equipment needs.

Explore our range of products backed by industry-leading warranties, and let us support your business every step of the way.

Give us a call or shoot us a message to start a conversation about your kitchen needs today!

by BSR Marketing | Dec 2, 2024 | Uncategorized

What’s the Difference Between Purchasing Efficient Versus Inexpensive Equipment?

When outfitting your commercial kitchen, the choice between purchasing quality and inexpensive foodservice equipment can significantly impact your business’s efficiency, costs, and overall longevity. Let’s dive into the crucial differences and why investing in quality equipment, especially through a trusted local provider (like us!) usually pays off in the long run.

The True Cost of Frequent Replacement

Inexpensive Equipment:

- Frequent Breakdowns: Cheaper equipment tends to break down more often, leading to frequent repairs and replacements.

- Hidden Costs: While the initial purchase price may be lower, the cost of downtime, repairs, and eventual replacement can add up quickly.

Quality Equipment:

- Durability: High-quality equipment is built to last, reducing the need for frequent replacements.

- Long-Term Savings: Though the upfront cost is higher, the long-term savings on repairs and replacements can be substantial.

Labor Savings

Inexpensive Equipment:

- Inefficiency: Cheaper equipment often lacks the advanced features and reliability needed for efficient operation, leading to longer preparation times and increased labor costs.

- Training Time: Inconsistent performance can require additional training time for staff to learn how to work around equipment quirks.

Quality Equipment:

- Efficiency: High-quality equipment is designed with efficiency in mind, allowing your staff to work faster and more effectively.

- User-Friendly: Reliable, easy-to-use equipment reduces the learning curve and allows staff to focus on their tasks rather than troubleshooting issues.

Efficiency and Cost of Ingredients

Inexpensive Equipment:

- Inconsistent Results: Cheaper equipment may not maintain consistent temperatures or perform reliably, leading to wasted ingredients and inconsistent food quality.

- Higher Waste: Inconsistent performance can result in higher food waste, impacting your bottom line.

Quality Equipment:

- Precision: High-quality equipment ensures consistent results, reducing waste and ensuring your ingredients are used efficiently.

- Better Food Quality: Consistent performance means better food quality, which can lead to higher customer satisfaction and repeat business.

Working with a Local Expert: A 3rd Generation Idaho-Based Company

When it comes to making these important equipment choices, working with an experienced local provider can make a world of difference. Here’s why partnering with a 3rd generation Idaho company, such as ourselves here at BSR, who understands your menu requirements can be beneficial.

Expertise and Experience:

- Generations of Knowledge: A 3rd generation company brings decades of experience and industry know-how. They’ve seen the evolution of foodservice equipment and understand what works best in various scenarios.

- Tailored Solutions: They focus on your specific menu requirements, ensuring that you purchase equipment that performs exactly as you need it to.

Personalized Service:

- Consultative Approach: Unlike big-box retailers, a local expert can provide personalized consultations, helping you select the equipment that best fits your needs

- After-Sales Support: They offer ongoing support and maintenance services, ensuring your equipment stays in top condition.

Community and Trust:

- Local Presence: Being part of the local community means they are more invested in your success. Their reputation is built on trust and long-term relationships.

- Quick Response: Proximity means faster response times for service and support, minimizing any downtime.

Real-World Impact:

- Energy Efficiency:

- Inexpensive Equipment: Often lacks energy-efficient features, leading to higher utility bills.

- Quality Equipment: Incorporates advanced energy-saving technologies, reducing your operational costs.

- Maintenance and Support:

- Inexpensive Equipment: May come with limited warranties and support options.

- Quality Equipment: Typically offers extensive warranties and reliable customer support, ensuring any issues are swiftly addressed.

- Resale Value:

- Inexpensive Equipment: Depreciates quickly, offering little to no resale value.

- Quality Equipment: Maintains a higher resale value due to its durability and brand reputation.

Conclusion

Investing in quality commercial foodservice equipment is an investment in not only your current operations but, equally so, your business’s future. While the initial cost may be higher, the benefits of durability, efficiency, and long-term savings make it a much smarter choice.

Partnering with a trusted, experienced local provider can further ensure you are getting the best equipment for your needs, backed by personalized service and support. Remember, in this fast-paced world of foodservice, the reliability of your equipment can directly impact your success. Choose wisely and, as a result, your kitchen will run smoothly, efficiently, and cost-effectively.

Outfitting your kitchen with the right equipment can transform your operations, enhance food quality, and ultimately boost your bottom line. Don’t let the allure of lower upfront costs lead to higher long-term expenses. Opt for quality and work with a local expert to make sure your kitchen is the best it can be (and we would love to be the one you choose to work with!)

Ready to Invest in Quality?

If you’re ready to elevate your kitchen’s performance, explore our range of top-tier commercial foodservice equipment designed to meet your every need. Let’s make your kitchen the best and most efficient it can be.

Ready to upgrade? Let’s talk. Give us a call today! (800) 368-3181.

by BSR Marketing | Oct 23, 2024 | Uncategorized

In the bustling world of foodservice, your choice of supplier can make or break your operation. Like a good soufflé, it’s all about having the right ingredients, precision, and a pinch of flair. Enter BSR Design & Supplies, the culinary partner you never knew you needed but can’t live without.

- BSR Doesn’t Do Cookie-Cutter Solutions

You’ve got a vision for your food operation, and it’s definitely not “just like everyone else’s”. No matter what type of foodservice operation you’re running, BSR gets it. We pride ourselves on tailored solutions—meaning we don’t provide a generic “one size fits all” plan on your business. We’ll listen to your specific needs, whether you’re a Chef needing more firepower on the grill or a catering specialist tired of equipment that malfunctions mid-event. In short: we design around YOU.

- Expertise Served Fresh Daily

Our team isn’t just made up of salespeople flipping through product catalogs. We’re seasoned pros—think culinary masterminds crossed with equipment nerds. We know what works in a kitchen, and we definitely know what doesn’t. BSR’s product line is curated with top-tier brands, ensuring you get durability and reliability with every piece of equipment, smallware gadget, and countertop. We offer advice that’s based on real world experience. If we recommend a product, it’s not because it looks shiny in a showroom—it’s because it will survive your most chaotic rush.

- Full-Service Experience: We Do the Heavy Lifting

Running a foodservice operation is hectic enough without having to chase down several different vendors to get the job done. With BSR, you’re not just buying equipment—you’re getting the full-service VIP treatment. We’re talking consultation, design, delivery, putting equipment in place, and especially after-sales support. We’re with you every step of the way. Need a last-minute fix? We’ve got your back. Kitchen layout looking more like a maze than a masterpiece? We’ll design a space that flows like butter in a hot pan.

- We’re Price-Savvy, Not Price-Obsessed

Sure, everyone loves a good deal—but nobody wants “cheap” at the expense of quality. At BSR, we strike the perfect balance: competitive pricing without cutting corners. We offer high-quality products that are built to last, and we’re savvy enough to know when a deal is truly good or just, well… not. Plus, our financing options make it easy for you to outfit your foodservice operation without blowing your budget.

- Customer Service That Doesn’t Phone It In

You know that feeling when you call customer service and are greeted by a robot that barely understands you? Yeah, we’re not about that life. At BSR, we pride ourselves on being human, responsive, and invested in your success. When you call us, you’re talking to a real person who knows their stuff—and, dare we say, actually cares. We’ll help you troubleshoot your foodservice equipment issues. If you’re not happy, we’re not happy. Simple as that.

- We’re Local, but We Think Big

Being a local business means we know the pulse of our community—we understand the unique challenges Chefs, restaurant owners, and catering pros face right here at home. But that doesn’t mean we’re behind the curve. Oh no. We bring the latest global trends in kitchen design and foodservice equipment right to you. Looking to add some high-tech tools that’ll make your competitors jealous? We’re on it.

- Chefs Trust Us, and So Should You

BSR Design & Supplies isn’t just a supplier; we’re the partner that top Chefs, restaurant owners, and catering companies rely on when they need equipment they can trust. Our reputation is built on quality, reliability, and a genuine commitment to the people we serve. When industry pros need top-notch gear, they know BSR delivers every time.

But don’t let us convince you – come in and see for yourself at one of our locations in Boise, Twin Falls, or Idaho Falls. Or give us a ring at (800) 368-3181. We’re here when you’re ready to start the conversation.

by BSR Marketing | Sep 9, 2024 | Uncategorized

Photo credit Innovo Kitchen.

Transitioning Your Food Operations from Summer into Fall

As the warm days of summer give way to the crisp air of fall, restaurant owners are about to face a pivotal moment of transformation. Instead of an inconvenience or a hassle of extra work, however, it should be greeted as an opportunity to refresh business strategies and regenerate what may be a lull in business especially as growth tends to become stagnant or excitement dulled over time. With the new season here, or just around the corner anyway, they must prepare for the changes that come with the change, accounting for everything from menu offerings to customer traffic.

Seasonal transitions bring fluctuations in customer preferences, menus, and even staffing needs. At BSR Design & Supplies, we’re here to offer our most sound tips to help the community of restaurant owners and all other food-operational professionals make the most of this provisional point.

1. Adjust Your Menu to Reflect Fall Flavors

The changing of seasons offers the perfect occasion to refresh your menu with ingredients and dishes that align with fall’s rich, hearty flavors. As the temperature cools, diners often seek out comfort foods that evoke warmth and coziness. Adapting your menu to highlight seasonal produce and bold flavors will not only appeal to your customers but also keep your offerings fresh and relevant, giving people a reason to continuously check back in their curiosity to stay current with rotating specials.

Our Recommended Strategies:

- Emphasize fall ingredients: Incorporate seasonal fruits and vegetables like squash, pumpkins, apples, cranberries, and root vegetables. These ingredients pair well with warming spices and offer rich flavors that complement cooler weather.

- Offer seasonal specials: Limited-time dishes can create a sense of urgency and excitement. Consider adding specials that feature hearty soups, slow-cooked meats, and warm desserts to your fall menu.

- Update drink offerings: Craft seasonal beverages like spiced ciders, pumpkin-flavored cocktails, and warm lattes to reflect fall flavors and attract more customers.

2. Prepare for Changes in Customer Behavior

The transition from summer to fall often brings shifts in customer traffic. Cooler weather, the return to school, and holiday planning can all affect when and how customers choose to dine. Adjusting your operations to align with these changes can help you maximize customer satisfaction and profitability.

Our Recommended Strategies:

- Reevaluate your outdoor dining space: If your restaurant relies on outdoor seating, start planning for cooler weather by adding outdoor heaters or transitioning guests inside. Create a warm and inviting atmosphere both indoors and outdoors to accommodate diners.

- Adjust your hours: Depending on your location, you may notice shifts in foot traffic as the days grow shorter and school resumes. Consider adjusting your hours to reflect these changes, focusing on peak dining times for fall.

- Run weekday promotions: If you notice a drop in lunchtime or weekday traffic, offer discounts or special promotions to encourage midweek dining. A “Back-to-School” or “Fall Harvest” menu could entice customers to dine with you during slower times.

3. Focus on Seasonal Marketing

Fall brings several marketing opportunities that you can leverage to keep your restaurant top-of-mind. The season is full of themes, from harvest festivals to Halloween, making it a perfect time to introduce fall-themed promotions and events.

Our Recommended Strategies:

- Launch seasonal promotions: Highlight fall-inspired dishes and drinks on your social media channels and website. Create eye-catching campaigns that showcase the warmth and coziness of your fall offerings.

- Host fall-themed events: Organize events such as harvest dinners, Oktoberfest celebrations, or themed happy hours. These events can drive traffic and create buzz, helping your restaurant stand out during the season.

- Prepare for the holiday season early: As fall is the precursor to the holiday rush, begin marketing your restaurant as a venue for holiday parties and group events. Offer early booking incentives to secure reservations before the season ramps up.

4. Ensure Your Equipment Is Ready for Cooler Weather

Fall can bring changes to how your kitchen operates, especially as you shift from lighter summer fare to heartier dishes that require different preparation techniques. Making sure your equipment is in peak condition will prevent costly disruptions and help you handle increased volume as you head into the busy holiday season.

Our Recommended Strategies:

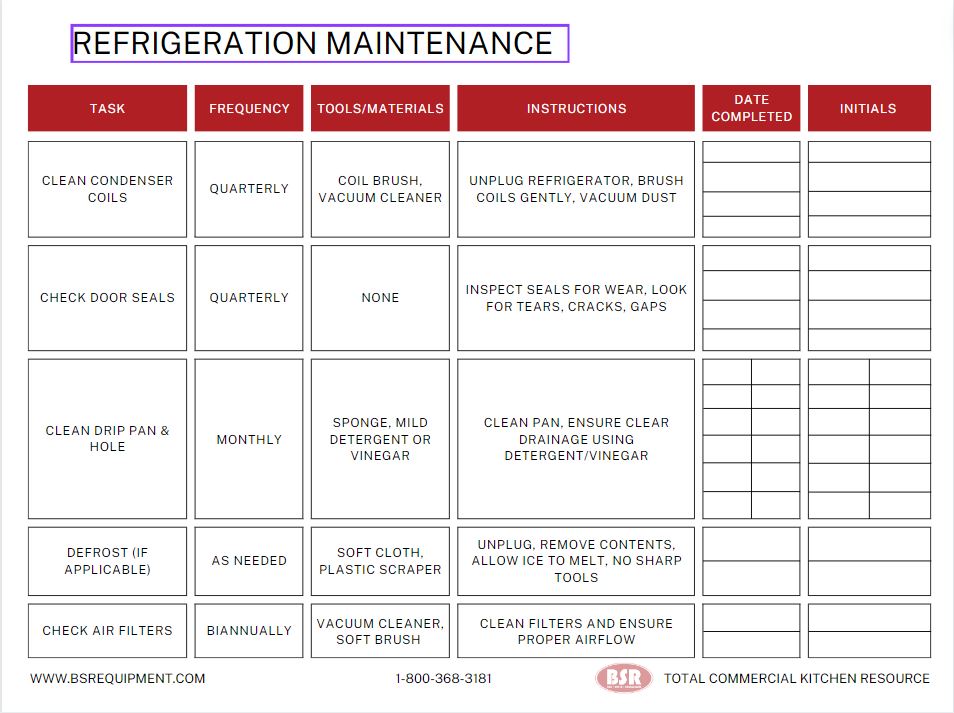

- Perform routine maintenance: Before the fall rush, conduct maintenance checks on key kitchen equipment like ovens, grills, and refrigeration units. Ensure everything is in working order to avoid breakdowns during high-traffic periods.

- Upgrade if necessary: If you’ve been putting off equipment upgrades, now might be the time to invest in more efficient tools. Whether it’s a high-capacity oven or improved refrigeration, upgrading equipment can increase efficiency and reduce downtime.

To Wrap It Up… (like the blanket you’ll be needing here soon)

As the summer months draw nearer to its finale, we emphasize the urgency that with the cooler seasons ahead (and not terribly far off!) it’s imperative to start thinking about what changes need to be initiated. The transition from summer to fall is an ideal time for restaurant owners and other professionals in the world of food operations to reassess their business approaches and make necessary adjustments to meet various seasonal demands.

At BSR Design & Supplies, we’re committed to supporting restaurant owners, catering professionals, chefs, and aspiring food-driven entrepreneurs alike – as well as everyone in between – every step of the way. From high quality kitchen equipment to seasonal supplies, we have everything you need to succeed as you transition into fall and beyond.

All it takes is a quick call in at (800) 368-3181 or visit to one of our locations in Boise, Twin Falls, or Idaho Falls, and you’ll be on your way to improved operations in no time! Maybe even pumpkin-spiced ones, if you prefer.

Or better yet, shoot us an email at [email protected] if you would like to receive our weekly close-out lists.

We’re here and ready to start a conversation.

by BSR Marketing | Aug 14, 2024 | Uncategorized

Photo credit Star Sugar Shack.

Starting a snow cone business can be both a fun and equally profitable venture, especially in warmer climates or during the summer season. While it doesn’t ensure your success, we thought offering a step-by-step guide would help you start and grow your snow cone business whether it’s a temporary endeavor or it happens to last a lifetime. So without further ado…

Step 1: Market Research and Planning

Research the Market:

- First and foremost, identify your target audience. Kids are usually the most obvious group that comes to mind but what about a focus on families? Or event-goers with the strategy to move around, setting up around concert venues and the like?

- Study your local competition. What do they offer? What are their prices? What can you do differently or better?

- Learn and understand the demand in your area, applying it to how you approach conducting your business. Are there enough events, parks, beaches, or just busy locations with enough foot traffic where a snow cone business could thrive?

Choose a Niche:

- Decide if you want to specialize in traditional snow cones, gourmet flavors, organic ingredients, or cones with any other specific theme.

- Think about seasonal variations or special offerings like combo deals with complementary snacks that pair well with shaved ice.

Create a Business Plan:

- Executive Summary: This is an important one as it will define the foundation. Outline your business concept, goals, and mission.

- Market Analysis: Detail your target market, competition, and marketing strategies.

- Business Structure: Decide on a business structure – is it going to be a sole proprietorship, LLC, etc.?

- Financial Plan: Estimate your startup costs, pricing strategy, and revenue projections. Once you’ve done that, it will be a lot easier to budget from there not to mention a reliable, organized bookkeeping system is essential for any business.

Step 2: Legal Considerations and Licensing

Business Name and Registration:

- This is the fun part! Choose a catchy and memorable name for your business.

- Register your business name with your local government.

Obtain Necessary Licenses and Permits:

- Food Vendor License: Required for selling food and beverages, so there’s no option for cutting corners here.

- Health Department Permit: Your equipment and setup must meet health and safety standards.

- Sales Tax Permit: Register for a sales tax permit to collect taxes on your sales.

- Any required parking permits if you choose to set up somewhere around town that requires one.

Get Insurance:

- Liability insurance is essential to protect your business in case of accidents or injuries.

Step 3: Equipment & Supplies

Purchase Essential Equipment:

- Snow Cone Machine: Choose a reliable machine that can handle the volume you expect. The last thing you want to worry about is not being able to keep up with all the orders.

- Serving Equipment: Stock up on cups, spoons, and napkins.

- Flavor Dispensers: Consider multi-flavor dispensers for efficiency.

- Freezer or Ice Storage: Ensure you have adequate storage for ice.

Source Ingredietns and Supplies:

- Ice: You’ll need a consistent supply of clean ice (we can help with that too!)

- Syrups: Offer a variety of flavors. Consider both classic and unique options.

- Toppings: Think about adding extras like fruit, candy, or condensed milk.

Set Up Your Workplace:

- Whether you’re using a mobile cart, food truck, or kiosk, ensure that it’s organized, clean, and attractive. And safe, of course.

Step 4: Location, Location, Location

Choose the Right Location:

- High foot-traffic areas are ideal, such as parks, beaches, or busy streets.

- Consider setting up at local events, fairs, sports games, or festivals.

Negotiate for Prime Spots:

- If you’re working at events or on private property, negotiate favorable terms with the owners or organizers.

Step 5: Branding and Marketing

Create a Strong Brand:

- Develop a logo and color scheme that’s appealing enough it will have allure on its own.

- Create a catchy slogan that captures the essence of your business.

Online Presence:

- Set up a professional website and social media accounts.

- Stay consistent with regular posts highlighting updates, specials, and pictures of your snow cones… and everything related to them.

Promotions and Advertising:

- Offer discounts or promotions to attract first-time customers. Initially getting them through the door is sometimes the biggest challenge.

- Consider loyalty programs where customers can earn a free snow cone after a certain number of purchases, similar to a punch card at coffee shops.

Engage with the Community:

- Sponsor local events or sports teams.

- Partner with schools or organizations for fundraisers.

Step 6: Operations and Customer Service

Hire and Train Staff (if needed):

- Ensure they understand food safety, customer service, and the ins and outs of your snow cone business.

Customer Experience:

- Create a fun, friendly atmosphere that makes customers want to return.

- Encourage feedback and use it to improve your business.

Manage Inventory:

- Keep track of supplies and be sure to re-order inventory before you run out.

- Monitor which flavors or products are most popular and adjust your offerings accordingly.

Step 7: Financial Management

Track Your Finances:

- Use accounting software to keep track of income, expenses, and profits.

- Set aside money for taxes and unexpected expenses. It’s oftentimes when you least expect it that it happens.

Pricing Strategy:

- Ensure your prices cover your costs and provide a healthy profit margin.

- Consider special pricing for events or bulk orders.

Expand and Grow:

- Once your business is stable, consider expanding to new locations, offering catering services, or adding simple products to your menu lineup like popcorn, nuts, or cotton candy to increase the value customers feel like they are getting.

Step 8: Review and Adapt

Evaluate Performance:

- Regularly review your sales data, customer feedback, and market trends. Without the right (and consistent!) evaluation, how are you going to know how you’re doing?

- Be ready to adapt your strategy based on what’s working and what’s not. Don’t get too comfortable or set in stone. Pivot when necessary.

Innovate:

- Keep your menu fresh with a constant rotation of new flavors or seasonal offerings. It keeps people on their feet!

- Explore partnerships with local businesses or event organizers to help both yourself out, and them. It’s a win-win for everyone and their brands.

Step 9: Scale Your Business

Franchising:

- If your business model ends up taking off and becoming successful, consider franchising as a way to grow even quicker.

Adding New Products:

- Diversify your offerings to include other cool treats or snacks. What about popsicles? Or baked goods? Or dare we suggest boozy shaved ice for the adults?

Step 10: Stay Committed and Have Fun!

Customer Relationships:

- Build strong relationships with your customers by being personable and consistent. That’s where the real business shines through even beyond the quality products.

Passion for the Business

- Enjoy what you do! Your enthusiasm will speak for itself in attracting customers and genuinely making your business a success.

Concluding Thought

This may just be a general guideline to help get you started but we think it’s a pretty decent start because by following these steps, you’ll be well on your way to establishing a successful snow cone business that not only meets but far exceeds customer expectations.

With that, we say good luck and let us know how we can help! Because we’re here to turn your visions into a reality. Give us a call or shoot us an email. Specifically, email us at [email protected] if you would like to receive our weekly close-out lists.

We would love to start a conversation, and find you what you’re looking for.